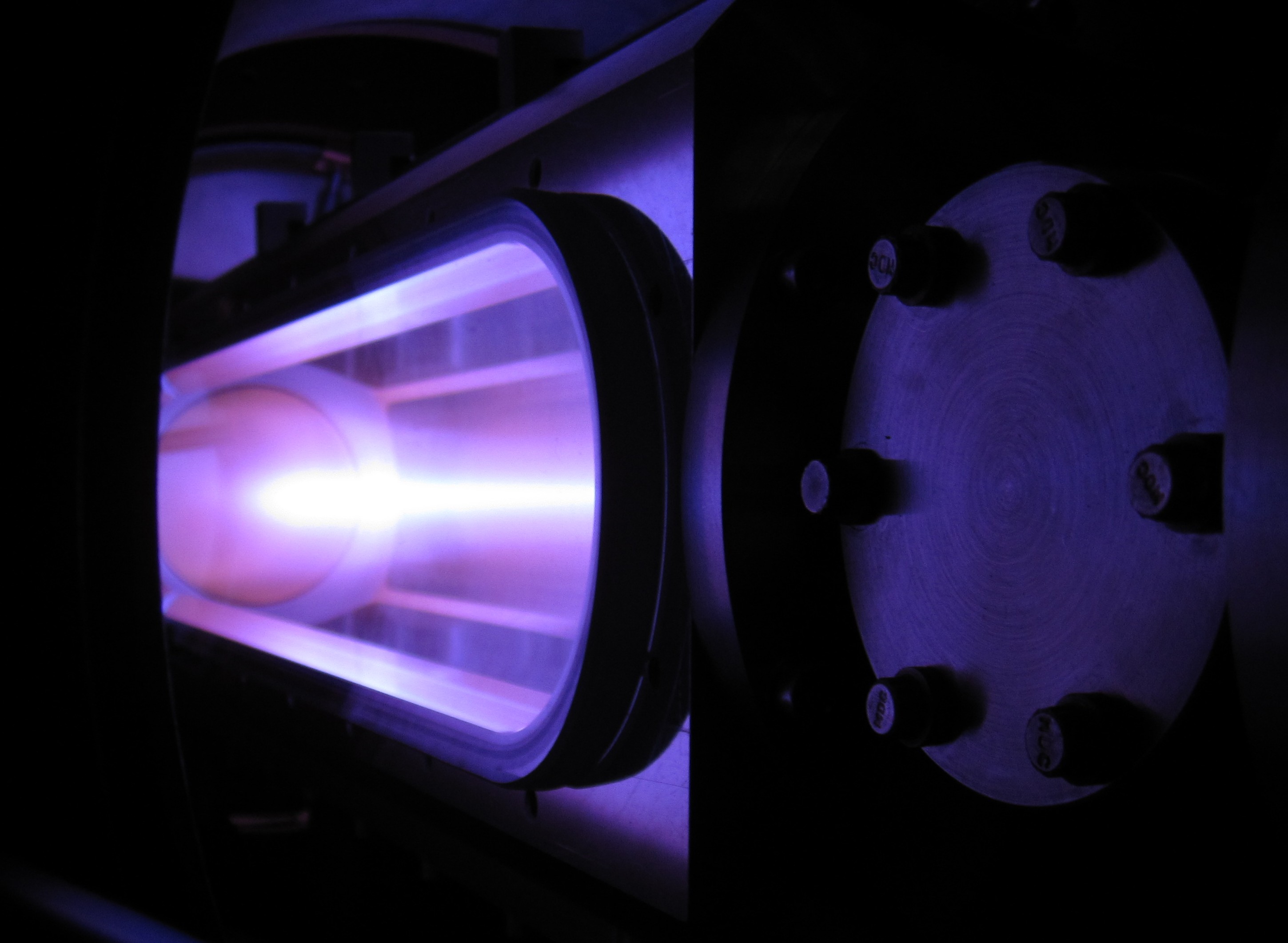

The metallizing can be applied through various processes, certainly the type of process called “PVD (Physical Vapour Depositation)” which consists in evaporating a metal in a very low pressure to allow the achievement of a homogeneous and thin layer that forms a coherent whole with the base substrate, is preferred for the uniform coating of the material capacity.

The traditional and consolidated aluminum metallizing has had great development for the following reasons: the simplicity of the production process, the ease of metal adhesion to the film, the deposit of the strong mechanical strength and the maintenance of product characteristics for a long time.

The primary purpose of the film metallizing process is the increase of the impermeability to gases, vapors, moisture and light whilst maintaining the typical characteristics of the type of material chosen for the application.

With the metallizing, it is deposited a thin layer of metal (usually aluminum) on a plastic film (or even on previously lacquered paper), by condensation of the metal vapor itself in a very low pressure chamber.

The metal functions are different:

- Give the film a reflective and shiny appearance for aesthetic and decorative patterns;

- Increase significantly the impermeability of the base film to gases and vapors, especially useful, in food packaging for the preservation of food;

- Constitute one partially shielding layer for the light in architectural or automotive applications;

- Constitute the electrode, a conductive dielectric multilayer structure (plastic film) for construction of electrical capacitors of wound-type “film”.